What do leading enterprises do to succeed with connected products and avoid the most common IoT challenges? Explore this guide and learn how to reach your IoT goals.

In this roadmap, based on our experiences from hundreds of IoT projects, we’ve compiled the typical reasons why companies don’t reach their IoT targets and outlined the steps you need to take to reach your goals with connected products.

For over two decades Telenor has successfully helped leading global enterprises with their connected products. During this time, we’ve witnessed IoT enable organizations, generate immense value, capture extraordinary opportunities, and realize significant efficiencies.

And yet, for every success story there are many more enterprises that struggle with their connected products. Many struggle to scale, some never reach the target volumes they set out to achieve, while others fail to unlock the business upside of IoT.

Even today, we continue to see substantial differences in how well companies launch IoT in their businesses, despite their best efforts. This leads us to an important question: Why do some companies succeed in reaching their goals while others do not? And likewise, how can you avoid the common mistakes that many enterprises make?

To better understand what differentiates successful IoT businesses from struggling ones, Telenor conducted a study into IoT deployments. The study revealed that only one in ten companies that launch IoT initiatives reach more than 20 percent of their targeted volume within the first three years. Similar figures are estimated by Gartner who shows that 75% of IoT projects will take twice as long as planned, with significant cost overruns.

Together with our partner Triathlon Group – who has led multiple digitalization and IoT journeys for industrial manufacturers – we have consolidated our learnings and compiled this roadmap to help enterprises avoid the biggest and most common IoT challenges. Consisting of a number of essential success factors and best practices, our strategic recommendations will help position enterprises optimally to avoid the biggest challenges so that they can focus on what they set out to do: truly capturing the value of IoT.

Digitalization is happening on a global scale, and leading industrial manufacturers are adapting to that by embracing new tech and new business models. Sometimes this means undergoing significant business transformation – moving from product-oriented business models into models where services receive a higher focus. The strategic rationale for many companies is the ability to provide additional customer value on existing products and to increase loyalty and stickiness by gaining a better understanding of the products usage and life cycle via real usage data. Cost savings and sustainability gains are also high on the agenda as connected solutions help to streamline operations, reduce on-site visits and offer new functionality with reduced hardware footprint. Connectivity is an important core enabler to realize the value of digitalization and secure that OEMs are connected to their product at any time and regardless of location.

Smart products are intelligent products that can network, collect, and communicate data. A smart product is generally connected to other devices or networks via different wireless protocols such as Wi-Fi, 5G, etc., that can operate to some extent interactively and autonomously. The term can also refer to a device that exhibits some properties of ubiquitous computing, including—although not necessarily—artificial intelligence.

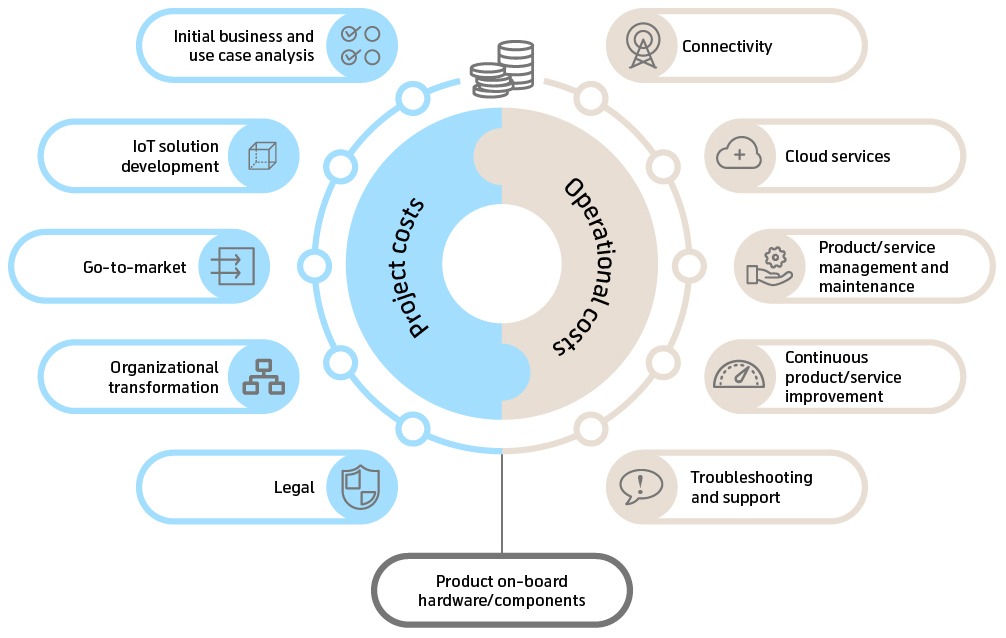

The total cost of ownership (TCO) per connected product is becoming a critical KPI for many companies as it, together with the predicted revenue, will decide the long-term profitability and return on investment (ROI) of the IoT solution.

As illustrated in the figure below there are several factors that impact the total time and cost of completing the first generation of the IoT solution. For industrial product manufacturers with product generations of 10-20 years, the generation lifecycle of the IoT solution has typically been 5-6 years. Companies must consider the cause-and-effect relationship between different costs, as lower costs in one area could lead to increased costs in another. As an example, a higher share of internal development leads to higher project costs and often longer time to market. This strategy may lead to lower operational costs over time once the solution is fully launched and stabilized. However, this also comes at a risk, as it puts higher requirements on reaching the targeted volume to keep the TCO in control.

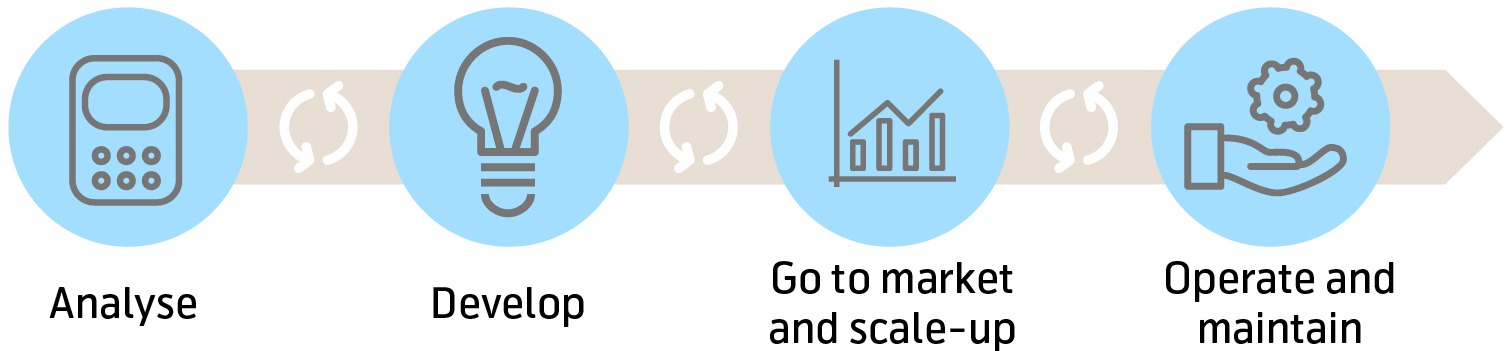

An IoT investment journey can be divided into the initial analysis of the business case, development of the technical solution, go-to-market and scale up, and finally operation and maintenance of the solution.

These stages in the lifecycle are interdependent and all decisions made will have an impact on the outcome in subsequent stages. Securing a cross-functional focus in all stages is essential to mitigating the risks and lowering total cost of ownership (TCO) of the IoT solution.

The four stages should be iterated back and forth in the beginning of the journey until a proof-of-concept has been reached, and also continuously throughout the lifetime of the solution.

In this white paper we will go through all four stages and the most important considerations during each stage.

For many companies, digitalization initiatives are launched to protect existing business by either maintaining innovation leadership or reacting to market development. It can initially be more of a strategic choice rather than an assessment of the exact business value of specific offerings. Even though this may help to secure executive management buy-in at a critical, early step, companies that are successful in launching IoT offerings at scale will always secure that the business value and rational of the IoT project is specific and clear.

Developing a solid business case that will last over time is difficult for many companies. Two especially challenging areas stand out; quantifying the value of the business cases and anticipating the future technical requirements of an IoT solution.

When identifying profitable business cases it is easy to overlook both external or internal perspectives of a solution. One key to success is to validate the value with intended users at the start to get early buy-in and insights into what benefits they experience from the solution. A good ambition is to be able to describe the use case in a one sentence value statement.

Companies today typically have relationships with their customers on many levels and in multiple functions such as delivery, installation, usage, maintenance, payment etc. A good practice is to ensure a cross-functional view at an early stage to ensure critical parts are not overlooked and to avoid having to revise work later.

A cross functional approach will also increase the chances of understanding future requirements as early as possible and help avoid that key requirements are missed completely. Insufficient analysis in the early stages can easily result in additional costs later. This could, for example, be costs for additional manual work needed during development and operations, which have not been accounted for in the business case.

Make sure you understand the business value and rationale.

Involve all internal and external stakeholders early to secure engagement and accountability.

In order to avoid IoT challenges, be agile and choose paths that enable flexibility in the early stages of your IoT journey.

Three main domains must be balanced when developing an IoT solution: business, processes, and technology. The business intention must be realized through processes and technology that supports the earlier identified use cases. Technology often receives the most attention of the three areas as companies struggle to overcome technical challenges in the development phase. The business dimension includes preparing the go-to-market strategy and updating the business model, while processes may require changed ways of working and new organization setups. Since the aspiration to find the perfect technical solution is often seen as the key to success, the importance of business and process transformation to create a successful IoT solution is often underestimated.

When developing the IoT solution there are some common challenges that should be addressed early to avoid costs later. One such challenge is that technical lock-ins may drive costly retrofits later in the IoT journey. This can be avoided by a dynamic development strategy where identified use cases are prioritized in a roadmap that also considers operational transformation needs related to the business or process side.

Another common challenge is integrating IoT solutions with existing business systems supporting organization processes (ERP, CRM, CMS). These integrations are often more complex to develop and maintain than anticipated, where matching and integration of data flows is especially complex.

It is critical for companies to understand internal resource and competence requirements for the complete lifecycle of the solution. After identifying current and competence gaps in the organization, a strategy can be set for how to close the gap e.g. through recruitments, outsourcing or partnerships. Outsourcing design, development or operations of the IoT solution can be a cost-effective alternative for managing limitations in capabilities and enabling faster time to market.

In other industries, buying the technology as a managed service is becoming increasingly common (e.g Salesforce or Office 365). A clear benefit of this is flexibility as it enables the solution to be scaled up at a known cost which facilitates better cost-effectiveness, predictability and reliability. The customer also gets a solution that is continuously enhanced and improved.

70% of companies say that they experience, or expect to experience within five years a shortage of skilled personnel in data analytics or IT management. (McKinsey)

In our discussion with customers, we experience that taking the solution to market does not receive the same attention as developing the technical solution.

Initiatives around digitalization often receive higher strategic attention from executive management, even though some initiatives may be more symbolic and with limited contribution to the bottom line. The business upside of an IoT solution will typically come from reduced internal costs or additional revenue streams through increased customer value. Both alternatives require different sales and implementation approaches. To conclude, the go-to-market approach is certain to change when introducing an IoT based offering and this change must not be underestimated.

With the help of IoT, many organizations envision their business model to transform from product sales, to additional service sales and later moving towards pay-per-use scenarios. However, to successfully transform a business model, it is critical to know your customers – to clarify the value and to secure stakeholder involvement. If your distribution model includes channels or partners, their roles and incentives should also be considered. When introducing changes to existing business models, this will typically impact multiple systems, processes, and several information flows within the organization. Important success factors are strong involvement from management and to start early (even with the commercial offering) at a limited scale and continuously iterate.

Selling services is more complex than selling a product, as it often requires deeper understanding of the customer business processes. In many cases the purchasing counterpart need to be redefined and the buying rationale described in different models. In addition, the nature of a service continuously being delivered over time will also set new requirements for how to organize sales and customer support over time.

Business leaders must secure a successful transformation of existing high performing sales teams to enable sales of services and bridge possible skills gaps that may paralyze a sales organization’s drive and performance. Investments need to be made to adapt the sales organization to the new offering. Sales competencies and ways-of working need to be seen as a strategic resource to strengthen capabilities to support customers. To build trust in the offering, it will be critical to convince the sales force about the need, performance or value enabled by the IoT solution or services. The new skills and understanding need to include the leaders in the company to lead the transformation successfully.

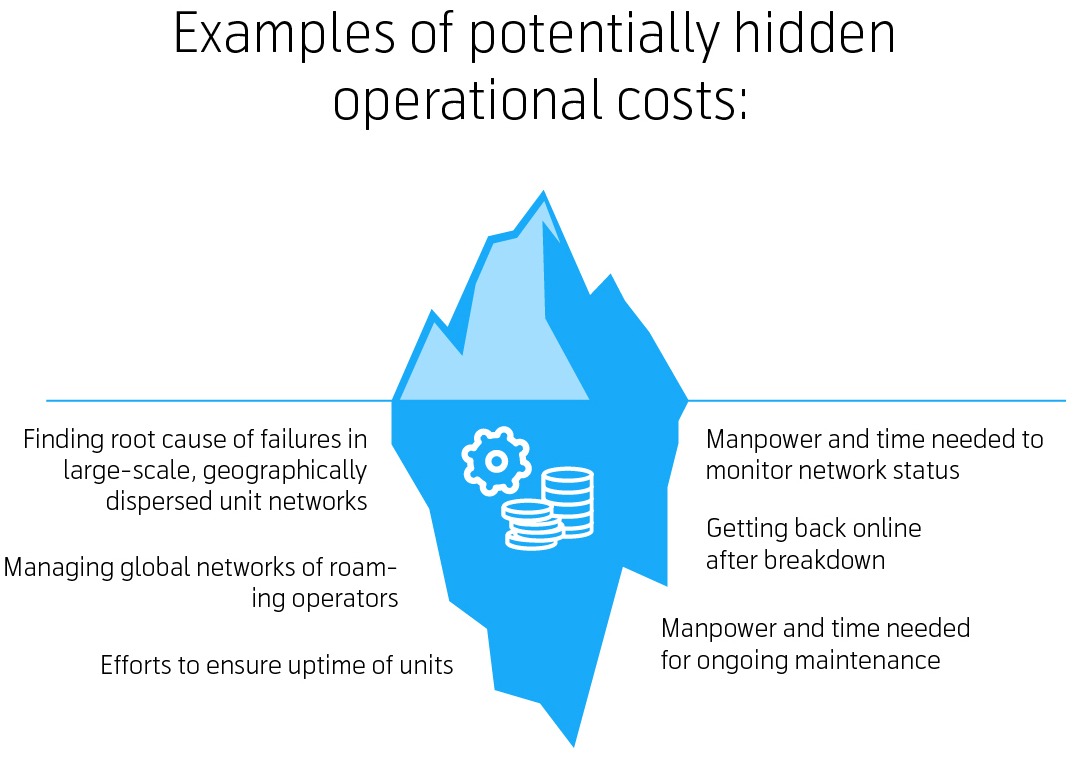

Once launched, long-term performance of the installed base needs to be sustained while keeping cost of operation at a satisfactory level – this is a big IoT challenge. To accomplish this, the product owner needs to have the right resources and tools to monitor and quickly address technical issues to minimize downtime and secure customer experience. As the installed base grows, manual intervention quickly becomes impossible and instead clear processes and more automation are required.

Monitoring status and addressing technical issues of deployed IoT units is resource intensive and may be associated with several potential hidden operational costs. If not managed properly, these costs could escalate quickly, especially for internal resources tasked with resolving issues. This in turn, could lead to temporarily or permanently needing to take the solution offline.

As previously pointed out, a success factor when launching a new IoT solution is the ability to quickly scale and reach targeted volumes and to generate value. As installed base increases companies must put additional focus on lifecycle management of the solution. IoT technology is new for many companies and the lifecycle of IoT solutions is still typically shorter than for the existing product lifecycle. For industrial product manufacturers with product generations of 10-20 years, the generation lifecycle of the IoT solution has typically been 5-6 years. This is due to upcoming technical development or legal requirements etc.

Some examples of key drivers towards new generations and new project investments are new standards and technologies, enforced security requirements and evolution of customer needs and value opportunities. Successful companies will monitor this and secure a clear and flexible approach on how to handle changes like, for example, new radio technology standards or data privacy regulations.

When moving to digital and connected solutions customer expectations of troubleshooting and response times increases dramatically and support is expected to be available 24/7. This can be particularly challenging if the source of the issue originates from one or several third-party suppliers. In such cases, the third-party has control of the response time, while the customer will continue holding your organization accountable. Partnering with a supplier that can supply and manage multiple parts of an IoT solution is an effective way of offering customers timely support by eliminating the number of fault-tracing handovers.

Here we summarize this white paper in three key success factors and recommendations that can help your company reduce time-to-market, secure focus on core business and ultimately reduce cost and improve overall customer satisfaction.

Ensure extensive focus on understanding and realizing the internal and external business value and secure that business value drives technology development, not the other way around. Furthermore, it is imperative that the sales organization and external distribution partners understand and have the capabilities to sell the new services and explain the added value. This starts with securing the sales team’s insights to ensure buy-in and trust in the solution.

Digitalization is a trend that affects every business, and the race has only just begun. Your ability to remain competitive depends on internal focus, resources and insights. Attracting the right talent is already a challenge, especially if IoT isn’t a part of your core business. Use partners for the parts of the IoT development that you don’t master within the organisation and use your own resources to focus on defining and developing the customer value proposition. Partnerships will help you manage your resource needs and give the flexibility to source the expertise you need. It will make your business more agile and allow you to become competitive and pick up and speed faster.

Missing to take maintenance into consideration early can quickly lead to high and unforeseen costs. Sustaining long-term performance of the installed base while keeping cost of operation at desired levels requires resources and tools to monitor and quickly address technical issues. Manual intervention quickly becomes impossible as the installed base grows.

Successful companies will monitor status, address technical issues and secure a clear and flexible approach on how to handle changes like, for example, new radio technology standards or data privacy regulations.

Trying to build “the perfect” solution from the beginning will typically lead to a higher risk of delays, overlooking or not identifying future business cases, or limiting ability to use new technology over time. We recommend a long-term investment plan with an agile approach and with staggered releases. However, while new functionality can be added continuously it is recommended to have a clear plan how to handle troubleshooting and customer support as the solution scales.